Coatings, Coverings & Backings

Coating in Nylon Fabric

PAZ / NFT

PAR / NFB

PAZ + PAR

NFT + NFB

Black Antistatic

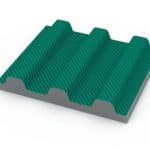

The special coating of polyamide fabric applied on the belts, allows a substantial reduction of the friction coefficient. Fabric applied on tooth (PAZ), reduces noise and friction which is key in conveyors with accumulation systems. Also available with antistatic properties.

PAZ / NFT: Coating on the teeth. Reduces the coefficient of friction

PAR / NFB: Coating on the back. Reduces the coefficient of friction

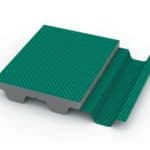

PAZ-PAR / NFT-NFB: coating on the teeth and on the back

Coefficient of friction

- Polyurethane on steel µ = 0,7

- PAZ-PAR on steel µ = 0,35

- Polyurethane on aluminium µ = 0,8

- PAZ-PAR su aluminium µ = 0,45

Coating in Polyurethane

85 Shore A

35/85 Shore A

35/85 Shore A

Herringbone 85 Shore A

Supergrip 35/85 Shore A

Ribbed 35/85 Shore A

The polyurethane offers the best wear resistance. Applications: industry of woodworking, ceramics, glass. On request, polyurethane coatings in accordance to FDA Regulation are available.

Coating in Rubber

Linatex 50 Shore A

Rubber 45 Shore A

APL 45 Shore A

Both natural and synthetic rubber coatings are available. Properties are high coefficient of friction and high resistance to temperature. Applications: paper industry, ceramics, wood processing, glass, labeling and packaging machines

Coating in PVC

48 Shore A

Supergrip 50 Shore A

PVC has a high coefficient of friction and a good resistance to acids. Applications: paper industry, ceramics, woodworking, glass, machines for labeling and packaging.

FDA certification allows the use of the product in the food industry.